SHOES: WHAT A PASSION

Watch NEW videos...

<<< Look at the video

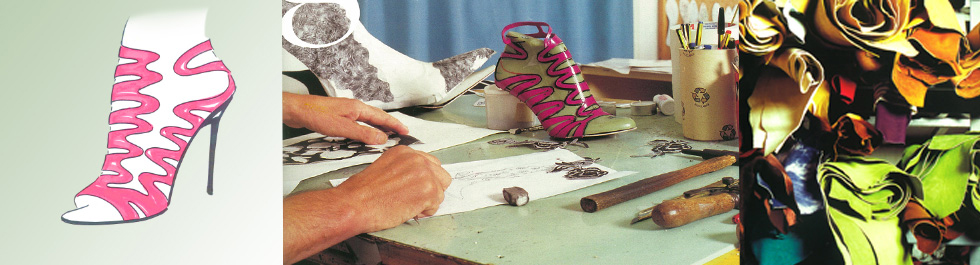

A shoe is a really fascinating accessory, with a unique structure: behind its project and realization there are specialized professionists for each step that cooperate to make an excellent product. Each phase is essential, because the perfect shoe is realized only through a total blend of all the elements.

STYLE

The last is realized after having decided the design and style of the collection, and that is the soul of the shoe. With great attention, sensitivity and sense of proportion, a piece of wood is polished and beveled until it becomes the structure – also called scaffold or body – on which the model is designed. Each millimeter is important and can influence the final result.

LAST

The last is realized after having decided the design and style of the collection, and that is the soul of the shoe. With great attention, sensitivity and sense of proportion, a piece of wood is polished and beveled until it becomes the structure – also called scaffold or body – on which the model is designed. Each millimeter is important and can influence the final result.

HEEL

Each shoe has its heel, spike heel, cone-shaped heel, Louis heel, covered with leather, metal or wood, polished or covered with rhinestones. It is a further touch of style, that essential factor that determines, together with the last, the final style of the product.

SOLE

Made of leather or rubber, with different thickness and manufacturing, the sole, too, contributes in defining the style of the footwear and influences the final effect.

MODEL

The chosen design is transferred on the last by the technician, who will realize on that model all the characteristics that will make it unique; for example overlapping, lashings, reinforcement, lining, pattern and decorations. Here the precision is vital: in this phase, the last maker and the shoe designer work together, as if they were one.

CUTTING

Kidskin, calf: only the expert hands of the person who cut leather can choose the best materials and recognize their quality. With their experience they avoid faults and enhance the product at its best, in order to obtain a perfect output from each material.

SEAMING OF THE UPPER

Here each part is linked by the expert hands of the personnel working in the seaming department. They refined the parts cut before and link them with the maximum care. The result, after this phase is an upper ready for the lasting.

LASTING

Once positioned on the last, together with the sole, the upper is put into tension on the tack lasting machine. After this phase, the heel and the sole are inserted. Then the shoe is cleaned up from the exceeding parts and, after having removed the last, an insole is added.

FINISHING

After many steps of polishing and straightening that make it perfect, the shoe is gently put into its box, wrapped in tissue paper, ready to be sold.